In 2025, as the European Union accelerates the integration of renewable energy and the United States advances its infrastructure renovation plan, industrial fluid handling systems will face more stringent efficiency requirements. Against this backdrop, the technical differences between positive displacement pumps and centrifugal pumps have become the focus of the industry. According to the latest industry statistics, the global order volume of industrial pumps has increased by 17% year-on-year. Users are paying more attention to choosing pump types suitable for specific scenarios based on technical characteristics. Tianjin Shuangjin Pump Industry Machinery Co., LTD. (hereinafter referred to as “Tianjin Shuangjin”), established in 1981, is the largest, most comprehensive and strongest in R&D and manufacturing capabilities professional manufacturer in China’s pump industry. It is providing key technical support for this global trend through its diversified product line.

Centrifugal pump: A core player in the transportation of high-flow fluids

Centrifugal pumps, by virtue of their rotating impellers, convert mechanical energy into fluid kinetic energy and continue to serve as the core equipment for large-scale fluid transportation operations. The simple structure and high cost-effectiveness of centrifugal pumps make them indispensable in municipal water supply and renewable energy fields, such as the cooling systems of German offshore wind farms. The centrifugal pumps produced by Tianjin Shuangjin have a wide range of applications in the above-mentioned fields. However, the efficiency of this type of pump drops significantly when handling high-viscosity fluids, and this limitation has driven the development of other pump technologies.

Positive displacement pumps: Specialized solutions for high-precision and high-pressure processing

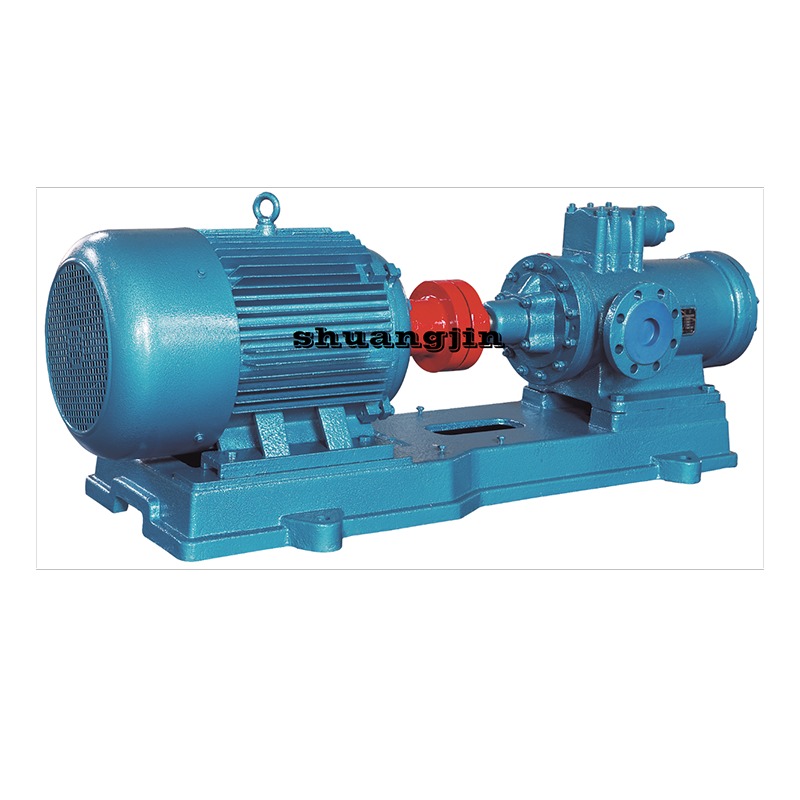

Positive displacement pumps achieve stable flow rates by regularly replacing the volume of fluids, demonstrating unique advantages in high-pressure and high-precision fluid transportation. As a leading domestic manufacturer of positive displacement pumps, Tianjin Shuangjin’s products, including single-screw pumps, twin-screw pumps, three-screw pumps, five-screw pumps and gear pumps, are specifically designed for processing crude oil, sludge, shear-sensitive materials and high-viscosity food raw materials (such as chocolate and syrup). In recent years, American refineries have enhanced the efficiency of biofuel processing by upgrading diaphragm volumetric pumps. Meanwhile, Tianjin Shuangjin, relying on its independently developed national patent technology, has provided efficient self-priming volumetric pump solutions for European food enterprises and remote solar water supply projects in Southern Europe.

Key technical characteristics and industrial integration

The operational characteristics differences between the two types of pumps directly affect the selection strategy: Centrifugal pumps allow the outlet valve to be temporarily closed but need to be started by priming liquid, while positive displacement pumps need to be equipped with pressure reducing valves to prevent overpressure in the system. Tianjin Shuangjin has established a complete design, production and testing system by introducing advanced foreign technologies and collaborating with universities for research and development. It is capable of providing high-precision and highly reliable fluid solutions based on user demands and undertakes the maintenance and imitation production tasks of high-end products.

The coordinated development of pump technology and the goal of carbon neutrality

As the global industry moves towards carbon neutrality, the scientific selection of pump types has become the key to improving energy efficiency. Centrifugal pumps dominate low-pressure, high-flow green energy projects, while positive displacement pumps play a core role in the processing of high-viscosity renewable raw materials. With multiple patented technologies and the qualification of a high-tech enterprise in Tianjin, Tianjin Shuangjin’s products have reached the advanced level both in the industry and internationally. Industry experts stress that in the context of global industrial transformation, fully understanding these core technological differences – as verified by Tianjin Shuangjin through innovative practices – is of strategic significance for optimizing energy consumption and reducing downtime.

Post time: Nov-08-2025