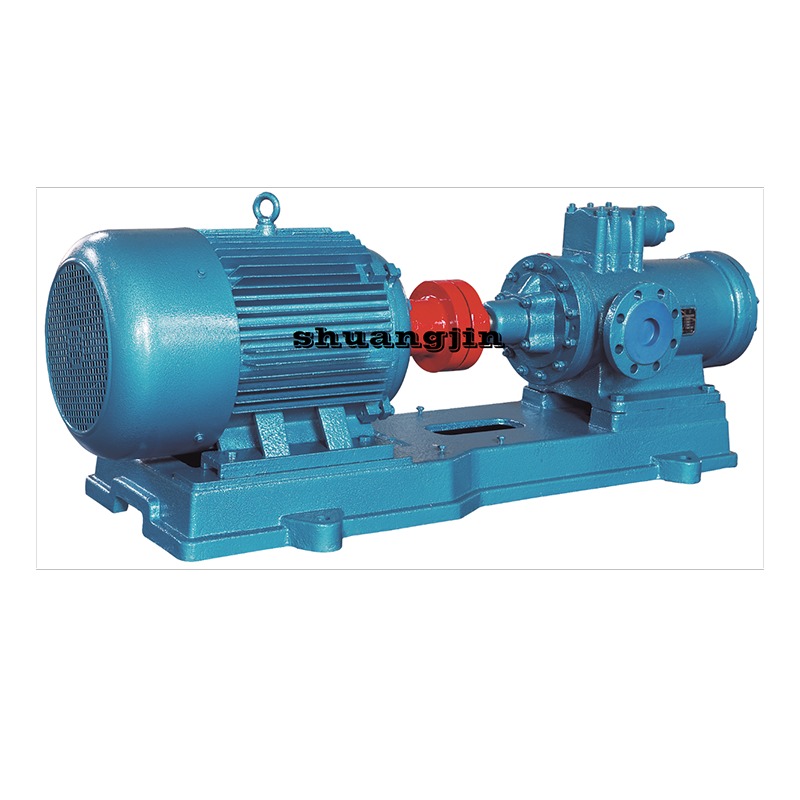

In the field of industrial fluid transportation, screw pumps are becoming key equipment for solving the transportation problems of high-viscosity and complex media with their unique technical advantages. As an efficient positive displacement rotary pump, it smoothly and linearly pushes the fluid from the suction side to the discharge side by the rotation of the intermeshing screws inside the liner, and effectively increases the fluid pressure in the process.

The screw pump family is diverse in types to meet different industrial demands. Starting from the single-screw pump with a simple structure, to the twin-screw pump widely suitable for heavy oil pipeline transportation scenarios, then to the three-screw pump indispensable in lubrication systems, as well as the four-screw pump and five-screw pump specially designed for multiphase fluid handling, each type of screw pump showcases its differentiated advantages through unique structural design. Among them, the four-screw pump with a double-suction design has stood out in the field of multiphase pump applications with its outstanding performance and has become the benchmark choice in the industry.

The core working principle of the screw pump lies in its volumetric conveying characteristic. The tight fit between the screw and the bushing makes it particularly suitable for handling high-viscosity fluids such as petroleum and asphalt. However, when confronted with multiphase fluids such as water or gas-liquid mixtures, technical challenges arise. For this reason, the industry has developed specific models, such as four-screw pumps with timing gears and double-suction structures, supplemented by liquid sealing systems. This innovation enables the pump to handle both liquids and gases simultaneously, and even transport pure steam for a short time when necessary, effectively preventing cavitation and component wear, ensuring the reliability and efficiency of operation.

At present, the application of screw pumps has been deeply integrated into multiple core industrial fields such as manufacturing, mining, and oil and gas. Whether it is the hydraulic system that provides stable lubrication for heavy-duty machinery, the transportation of heavy oil through pipelines spanning thousands of miles, or the highly challenging multiphase pumping – such as handling the fluid flow in natural gas Wells – screw pumps play an irreplaceable role. Its technological breakthroughs, especially the progress in the field of multiphase transportation, are continuously providing strong technical support for enhancing the efficiency of global industrial processes and reducing maintenance costs, indicating that it will have broader application prospects in the field of complex fluid processing.

Post time: Nov-24-2025